This article can be read in full as originally reported by CIOReview.com.

Dell’s Chief Supply Chain Officer Kevin Brown recently authored an article in CIOReview.com about the benefits of a circular economy and how technology can lead our shift to one.

This is a change Dell strongly believes in.

According to U.N. estimates, there will be another billion people added to the planet by 2025. This growth will happen in the world’s least developed regions, presenting both a challenge and an opportunity. Why? Well, we’re currently in what is known as “ecological overshoot.” Our demand on natural resources is beyond the planet’s capacity to regenerate them.

As Kevin talks about in his article, waste products [in a circular economy] are economically and environmentally beneficial as inputs to be reintroduced into the value chain. When we reuse or transform them, we can generate tremendous opportunities.

It’s true that changing the way the world approaches the economy won’t happen immediately, and without significant effort. Our consumption habits, manufacturing processes and so much more all favor our existing linear model. This is more commonly called “take, make, waste,” and it’s a model that’ been in place for nearly 300 years.

Transitioning to a circular economic model, in which all resources have value and waste is eliminated, is an imperative but enormous undertaking that no one company can handle alone.

In September 2015 Dell joined the Ellen MacArthur Foundation’s Circular Economy 100 (CE100) program to collaborate with other business leaders who share our interest in accelerating the move toward a circular economy. We will work with CE100 members such as H&M, Philips and Unilever to develop new manufacturing approaches, identify new partnerships and share best practices for applying circular principles.

Kevin’s outlook is a positive one. And his examples of how technology will help “close the loop” and create a more circular—and promising—economy help paint the picture for how the shift is happening.

From the CIOReview.com article:

As pressures mount, disruptive leaders are going to find the ways to design, source and build to this circular method. I believe technology will lead the charge.

Let’s consider mobile technology. The population at large has demanded a transition from solely using large machines on desks to having powerful computing in our briefcases and pockets. This transforms the materials required to source and build to the way existing resources are used to do the same. Beyond untethering us from our physical desks, the mobility of technology has given rise to the sharing economy, where resources have higher utilization rates. Think about ride-sharing services, such as Uber, that use cloud computing (another less resource-intensive method) to pull data from data centers. Previously, this concept would be nothing more than note cards on a dorm bulletin board without our phones.

I invite you to read more in Kevin’s CIOReview.com article.

You can learn more about how Dell is leading the shift to a circular economy, and other ways we’re putting technology and expertise to work where it can do the most good for people and the planet at legacyofgood.dell.com.

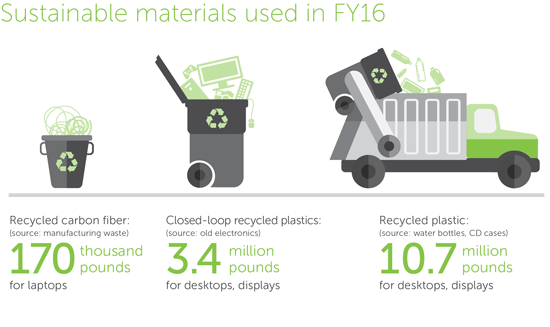

Dell created the industry’s first third-party certified, closed-loop plastics supply chain. Our closed-loop supply chain incorporates plastics from electronics recovered through our takeback services into the plastics used to make new Dell products.